Tag : drive

Schneider Electric ATV320U06M3C Altivar 320 Variable Speed Drive 0.55kW 3/4HP

Schneider Electric ATV320U06M3C Altivar 320 Variable Speed Drive 0.55kW – 3/4HP. Variable Speed Drive, Altivar Machine ATV320, 0.55 kW, 200…240 V, 3 Phases, Compact. We are NOT Authorized Distributor of this item. We sell SURPLUS and USED equipment ONLY. Designated trademarks, brand names and brands appearing herein are the property of their respective owners.

Categories: schneider

Schneider Electric Altivar 320 ATV320U55N4B Variable Speed Drive 5.5 kW, 7.5 HP

Schneider Electric Altivar 320 ATV320U55N4B Variable Speed Drive 5.5 kW, 7.5 HP. This is brand new and sealed in the box. The open box pictures are of one that was opened for pictures. You will receive a brand new and sealed unit.

Categories: schneider

Schneider Electric ATV320U06M3C Altivar 320 3/4HP Variable Speed Drive 0.55 kW

Schneider Electric ATV320U06M3C Altivar 320 3/4HP Variable Speed Drive 0.55 kW. This Product Has Been Installed And Project Canceled, And Finally Never Served. Less Than 10 Hours Of Operation. Variable Speed Drive, Altivar Machine ATV320, 0.55 kW, 200…240 V, 3/4 hp, 3 Phases, Compact. We are NOT Authorized Distributor of this item. We sell SURPLUS and USED equipment ONLY. Designated trademarks, brand names and brands appearing herein are the property of their respective owners.

Categories: schneider

ATV320U02M3C Schneider Electric Altivar 1/4 hp Variable Speed Drive 3 Phases

ATV320U02M3C Schneider Electric Altivar 1/4 hp Variable Speed Drive 3 Phases. This Product Has Been Installed And Project Canceled, And Finally Never Served. Less Than 10 Hours Of Operation. Product or component type. Format of the drive. Communication module, CANopen Communication module, EtherCAT Communication module, Profibus DP V1 Communication module, PROFINET Communication module, Ethernet Powerlink Communication module, EtherNet/IP Communication module, DeviceNet. [Us] Rated supply voltage. 200…240 V – 15…10 %. 0.18 kW for heavy duty. IP degree of protection. We are NOT Authorized Distributor of this item. We sell SURPLUS and USED equipment ONLY. Designated trademarks, brand names and brands appearing herein are the property of their respective owners.

Categories: atv320u02m3c

ATV320U02M3C Schneider Electric Altivar 1/4 hp Variable Speed Drive 3 Phases

ATV320U02M3C Schneider Electric Altivar 1/4 hp Variable Speed Drive 3 Phases. This Product Has Been Installed And Project Canceled, And Finally Never Served. Less Than 10 Hours Of Operation. Product or component type. Format of the drive. Communication module, CANopen Communication module, EtherCAT Communication module, Profibus DP V1 Communication module, PROFINET Communication module, Ethernet Powerlink Communication module, EtherNet/IP Communication module, DeviceNet. [Us] Rated supply voltage. 200…240 V – 15…10 %. 0.18 kW for heavy duty. IP degree of protection. We are NOT Authorized Distributor of this item. We sell SURPLUS and USED equipment ONLY. Designated trademarks, brand names and brands appearing herein are the property of their respective owners.

Categories: atv320u02m3c

Schneider Electric Altivar 320 AC Variable Speed Drive ATV320U40N4C. (BIN-1.5.1)

Schneider Electric Altivar 320 AC Variable Speed Drive ATV320U40N4C. Most of our used equipment goes through basic power bench testing as well as general static testing. While some aspects are difficult to test entirely without full system setups, we strive to deliver good working equipment. Our customers come first, and we are always willing to resolve any issues! Always message us first with any issues. We endeavor to take good clear photos of our equipment that may show signs of normal use such as scuffs, scratches, or other blemishes. We also try our best to note cosmetic damage issues. Photos of listings with multiple quantities are only a representation of the item you may receive. Our equipment is acquired from industrial environments, maintenance upgrades, or other auctions. Send us your list of surplus for a price! Ask us for any electronic repairs you may need, or google us for a repair quote. Our in house technicians refurbish a wide range of high failure, obsolete parts such as: AC/DC Servo Drives, Amplifiers, Touch Screens/ HMI’s, Power Supplies, PLC’s, Sensors, and virtually any industrial Circuit Boards. DHL is available for international customers when you ask for a quote.

Categories: schneider

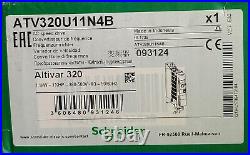

Schneider Electric ATV320U11N4B Altivar 320 Variable Speed Drive d8

Schneider Electric ATV320U11N4B Altivar 320 Variable Speed Drive d8. Breaker Hub specializes in the sales, purchasing, removal, rental, dismantling. Recycling, and relocation of electrical power distribution equipment.

Categories: schneider

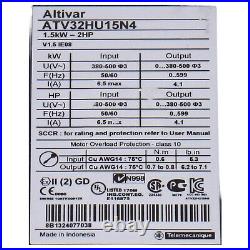

ATV32HU15N4 SCHNEIDER ELECTRIC, Variable speed drive ATV32 1.5 kw ATV32HU15

ATV32HU15N4 SCHNEIDER ELECTRIC, Variable speed drive ATV32 – 1.5 kw ATV32HU15N4? Monday – Friday: 0800 – 1800Hrs (CET). Unit of Measure: Unit(s). Packing Quantity: 1 Unit(s). Country of Origin: Indonesia. Year of Production: Upon Request. HS Code: Upon Request. Other: Variable speed drive ATV32 – 1.5 kw – 400 V – 3 phase – with heat sink, Main, Range of Product, Altivar 32, Product or Component Type, Variable speed drive, Product destination, Asynchronous motors, Synchronous motors, Product Specific Applic. The pictures in this add were taken from the item (or from of the lot) that is being offered. We spend a lot of time on making good, detailed pictures and on collecting and presenting all available product data in order to be as precise and complete as possible. However, if data is incomplete or not correct, we can not be held responsible. Are all being accepted by us. The mentioned prices exclude VAT. Please inform us your company VAT number in advance or while ordering so we can adjust invoice based on 0% VAT. If your company is located in The Netherlands 21% VAT is always required. Express is possible to any country in the world. EXW or FCA, Rijksweg 110, Dorst, The Netherlands (EU). We will need your invoice as well. Please note that all our articles are visible and unvisible coded and sealed. We will need pictures of the item and package in advance for first approval of return procedure. After the item has been checked and inspected by our Quality Manager we will inform you about the status. The transport costs are not refundable. Is a dynamic company with a clear focus. Turn the world of brand new and industrial obsolete products upside down! We believe we can do it better, more transparant and more sustainable. Together with our sister company TBWB B. We already have over 40 years of experience in industrial automation and completed many projects succesfully at OEM’s, Wholesalers and Distribution Centers (DC’s). As such we helped many companies in reducing their OPEX and CAPEX. In addition, with PLC2Day, we focus on reducing waste and giving the obsoletes a second chance. Our core program is. Automation (Siemens, SEW, Lenze, Fanuc, Mitsubishi, Allen-Bradley, etc). Pneumatics (Festo, SMC, Norgren, etc). Bearings (SKF, FAG, INA, Timken, etc). Hydraulics (Rexroth, Aventics, etc). Tools (Facom, Knipex, Stahlwille, etc). The people working at PLC2Day are full of enthusiasm and are highly driven to do things better every single day. Working at PLC2Day means working in an informal, open and challenging environment where you have room to develop yourself. Last but not least make a lasting contribution to the success of PLC2Day. At PLC2Day we promote availability, flexibility, cost efficiency and sustainability. We offer our partners.

Categories: atv32hu15n4